We’re Delivering The Premium Quality Of Rice World Wide.

Our Mission

Our Mission is to be the industry's top-ratede provider of Rice Verities targeting satisfying the most to our clients.

Our Vision

Our Vision is to be a top Rice Exporter Company in World and progress in our current position in the market.

Our Working Process

01

01

Paddy Purchases

We focus on the best Quality Paddy for it Reproduction.

02

02

Reprocessing

We focus on the best practices for the Reprocessing of The Paddy and convert it into Rice.

03

03

Packing & Sale

We focus on the best practices for its Premium Packing and Export Quality.

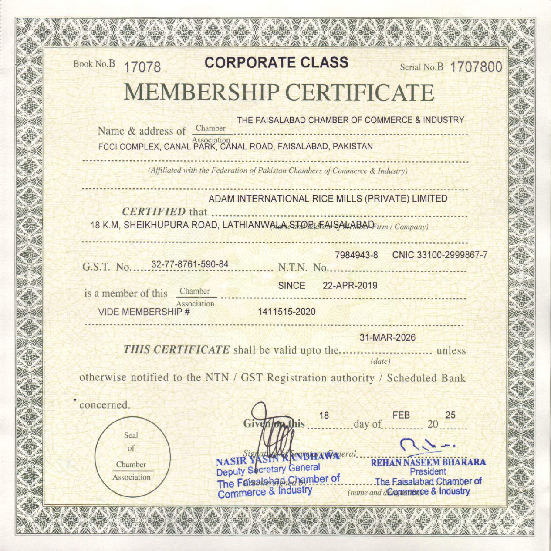

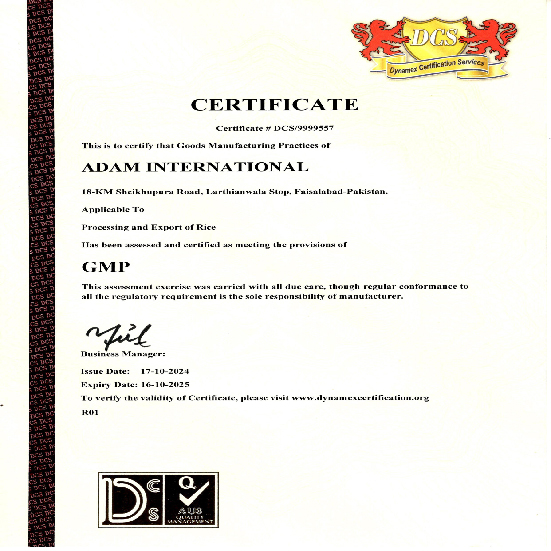

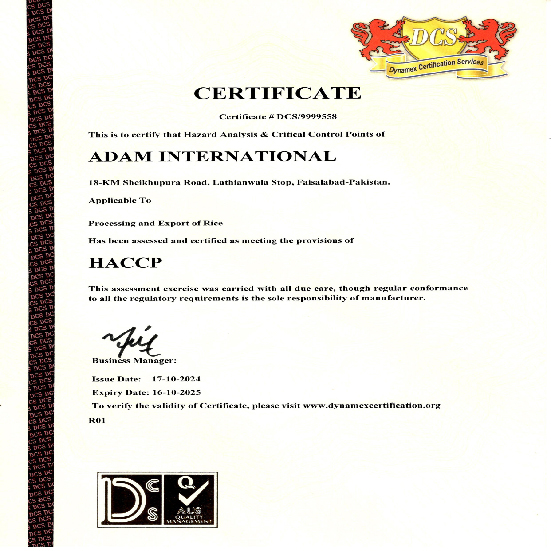

Our Achievements

Our Portfolio

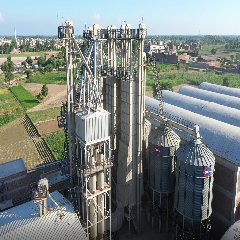

Adam International Rice Mills PVT Ltd.

Adam International Rice Mill has established itself as a global leader in premium rice production and export since its founding. Specializing in basmati and specialty rice varieties, we combine traditional expertise with cutting-edge technology to deliver exceptional quality grains to markets worldwide.

1. Sourcing Premium Paddy

- We procure the finest raw paddy from trusted farmers and suppliers.

- Strict quality checks are conducted to select only the best grains for milling.

2. Cleaning & Husking

- The paddy is thoroughly cleaned to remove dust, stones, and impurities.

- It then passes through dehusking machines to remove the outer husk, producing brown rice.

3. Polishing & Whitening

- The brown rice undergoes polishing to achieve the desired whiteness and texture.

- Advanced milling technology ensures uniform grain size and minimal breakage.

4. Sorting & Grading

- Rice is sorted using high-tech graders to separate broken grains and ensure consistency.

- Laser sorting machines detect and remove discolored or defective grains.

5. Quality Testing & Lab Analysis

- Samples are tested for moisture content, purity, and nutritional value.

- Compliance with **international food safety standards** (ISO, HACCP, etc.) is verified.

6. Packaging & Branding

- Rice is packed in **customized bags** (PP woven, jute, or vacuum-sealed) as per buyer requirements.

- Labels include essential details like variety, weight, and certifications.

7. Storage & Logistics

- Processed rice is stored in **climate-controlled warehouses** to maintain freshness.

- Efficient logistics ensure timely delivery to domestic and international markets.